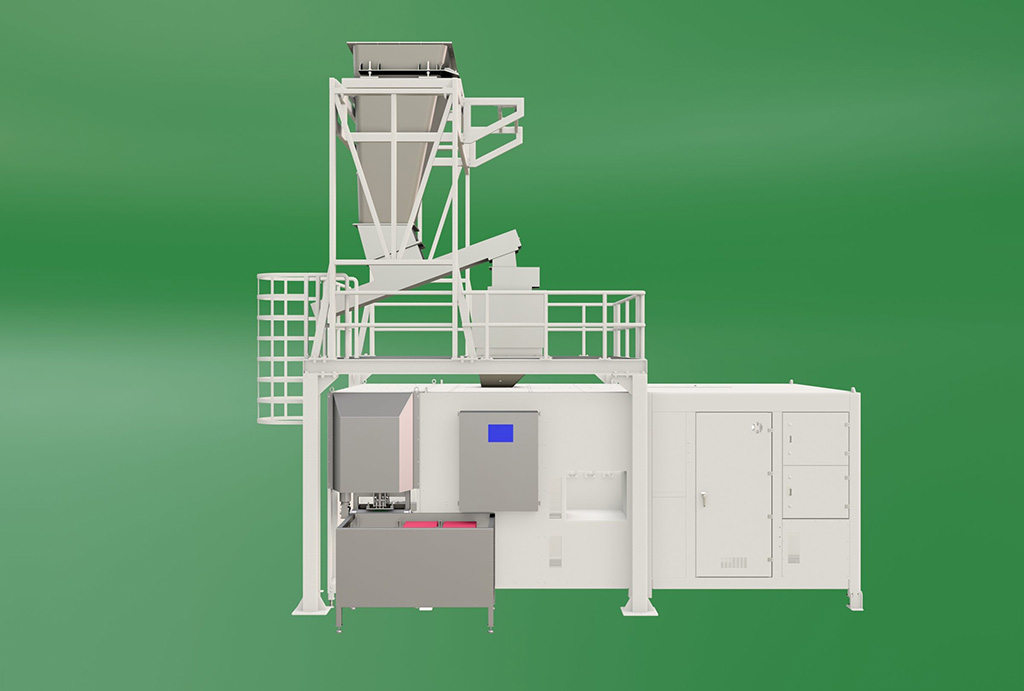

RoPac Machine

ROPAC® MODEL S

Two standard models are integrated with 6-axis robotic arm for high performance and flexible operation, applied with 1-layer bag or 2-layer bag with inner PE layer.

RoPac®- S1210 Automatic packing with single layer bag

RoPac®- S2208 Automatic packing with double layer bag (with PE inner)

ROPAC® MODEL H

Two high-end machines specifically designed for industries with highly corrosive materials, using either SUS304 or SUS316 material for fabrication. Integrated 6-axis robotic arm for high performance and flexible operation, applied with single layer or double layer bag with inner PE layer.

RoPac®- H1210 Automatic packing with single layer bag

RoPac®- H2208 Automatic packing with double layer bag (with PE inner)

Characteristic

- Suitable for 2-layer bags with inner PE layer

- Material for fabrication

- Open – mouths bagging

- Sealing PE technical

Application

- Type bags: PP, Kraft, HDPE

Special with Inner PE

- Fill range: 10 to 50Kgs

- Edge bags: Option

- PE bag sealing: Option

- Bag closing type: Option

Specifications

- Capacity: 8 -10 Ton/h

- Integrated 2 robotic arms

- Communication: In accordance with industry

- User-friendly operation interface

- Power requirements: 380/50Hz *

- Pressure requirements: 6bar/0,6MPa

- Air consumption: 1-1,5m3/min **

* Installed power depends on number of conveyors & main equipments

** Depends on machine operating mode, speed

RoPac®- D is a dual machine series, specifically designed for factories with narrow space, product lines arranged close together.

Options

- Sewing head

- Inkjet Printer

- Net weigher scale