With rising labor costs, the need for a safe working environment, and continuous operation, robotic palletizing systems are an intelligent choice to increase accuracy, reliability, and efficiency.

What is Robot Palletizing?

Robot Palletizer is a type of Robot specially designed for the stages of palletizing products. Application products include cartons, bags/bags, boxes, crates, etc., instead of workers in many industrial production fields.

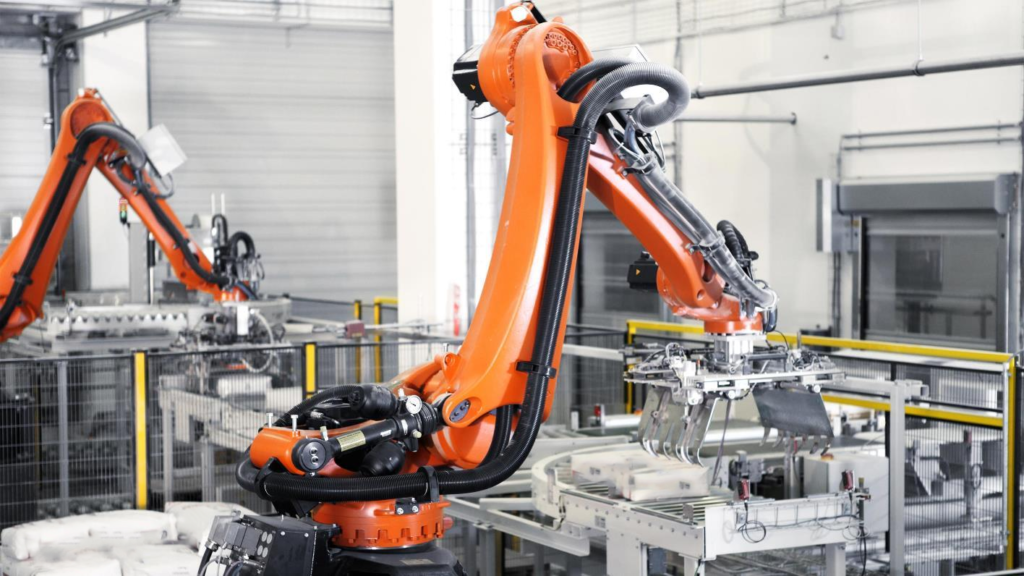

How does Palletizing Robot work?

The conveyor system delivers the packaged product to the robot location. A pallet is brought into the loading area by an automatic pallet dispenser or by a robot. The robot picks up products at the pickup position and then places them on the pallet quickly and accurately. After stacking products on the pallet in layers, the pallet is taken out of place through a conveyor belt to the succeeding processing stages. The robot repeats the process with a new pallet.

The robotic palletizer is customizable to suit each product type: containers, bags, carton boxes, plastic boxes, etc…, and flexible in layout to suit your requirements.

Pallet Software

The built-in software allows customers to operate and edit palletizing patterns on the HMI screen. These applications improve the speed and accuracy of current cargo handling processes and can adapt to future operational needs.

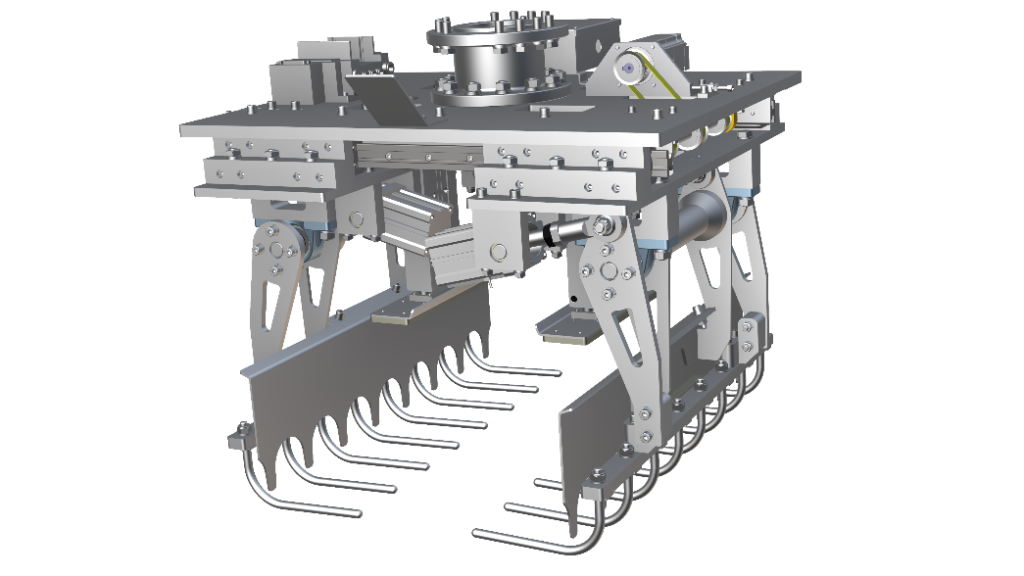

End of Arm Tooling

Custom-designed (end-of-arm tooling) expands the robot’s capabilities to accommodate a wide range of sizes and product types, fully automating the palletizing process with no additional equipment.

Application of Robot Palletizing

Robots use to stack in many different cases, many other functions such as check weigher, flattening (for packaging products), labeling, printing codes with many shapes and sizes, weight and material including carton box, plastic box, and aluminum or metal box, packaging type 1 layer or 2-layers.

Our engineering team designed and built palletizing solutions for many applications in industrial environments, where products are hard to handle, heavy, and hazardous. By installing these custom systems, customers reduce many operational hazards production activities faced by their workforce.

Benefits of Automating The Palletizing Process

Solve work accidents, and labor problems include:

- Working speed is not high

- Risk of injury

- Low cargo capacity

- No time consistency at work

- The ability to synchronize on the pallet is low (goods are unequal, unstable, etc)

- Labor cost

Solve long-term economic problems

Although Robot Palletizer has a high initial investment cost, it will pay back that cost over time, even if only in the short term.

Save production space

Robot Palletizing can complete work in tight spaces but is not overloaded due to their perfect coordination ability. Thereby businesses can take advantage of the remaining space to do other categories.

System components

Robotic palletizing systems typically include the following components:

- Conveyor: transfer product to Robot position.

- Check Weigher (Option): Check the product’s weight.

- Vibrating, pressing the bag: Evening the ingredients and flattening the bag (used for packaging products).

- Automatic Pallet Feeder: Automatically feed pallets to the packing position.

- PE film wrapping machine (Option): Automatically wrap PE film to protect the product

- Automatic label printer ( Option ): Automatically prints stickers according to the information set on the pallet.

- Safety fences and devices.

- SCADA monitoring control system.

Depending on customer needs, the device can be customized to suit that.

Technical team development, integrated solutions, and pre-and post-project care contribute to the overall success of a project. Fuji Technology commits to providing efficient cargo handling solutions that bring high value to investors.

Pingback: buy enclomiphene price in canada

Pingback: canadien kamagra en ligne

Pingback: buying androxal purchase in canada

Pingback: cheapest buy flexeril cyclobenzaprine uk where buy

Pingback: get gabapentin generic canadian

Pingback: online order fildena usa overnight delivery

Pingback: itraconazole ordered from australia

Pingback: staxyn no perscription next day delivery

Pingback: discount avodart on line

Pingback: xifaxan at discount price

Pingback: discount rifaximin generic version

Pingback: kanadský kamagra vs spojené státy kamagra